Main Page/PHYS 4210/Semiconductors II

Semiconductors II

Introduction

This laboratory extends your understanding of semiconductors from the first part, where the conduction mechanism in a single-zone doped sample of germanium was investigated, to the so-called p-n junction. This junction forms the basis of semiconductor switching and amplification devices. A diode consists of a single p-n junction, while a simple transistor contains three zones assembled either as p-n-p, or n-p-n.

The concepts of charge carrier injection and excess carriers are introduced. Furthermore, the difference between ohmic and rectifying contacts is demonstrated, and the terms ‘emitter’ and ‘collector’ are explained. Experiments on the detection of carriers at the collector demonstrate the existence of excess carriers generated both by injection and optical methods. Measurements are made that allow us to calculate the mobility of these carriers, and a further experiment provides an estimate of their lifetime.

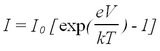

The physics of the p-n junction is explained in most textbooks on modern physics. Simple presentations are given, e.g., in refs. 1,2, which explain how the current-voltage characteristic of a diode (p-n junction) arises:

| (1) |

Make sure to understand the electric fields (and the potential) that arise across the three zones (pure p, pure n, and the depletion region that joins the two) and give rise together with the Maxwell-Boltzmann distribution for the charge carrier diffusion process to eq. (1).

The laboratory consists of three experiments:

- Investigation of the difference between ohmic and rectifying contacts. Measurement of the current-voltage characteristic (1).

- Verification of the existence of minority carriers created by injection. Measurement of the minority carrier mobility.

- Generation of minority carriers by optical means. Measurement of the minority carrier lifetime.

Experimental Procedure

The Apparatus

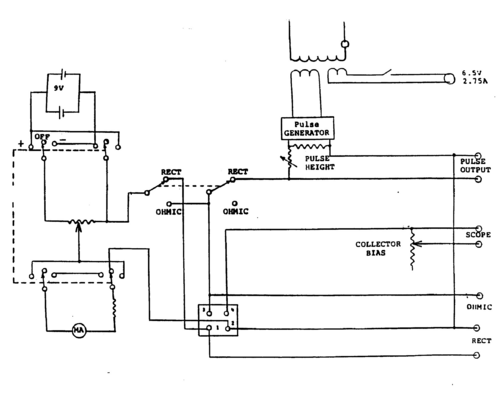

The Sample and Holder

The n-type germanium sample, ready prepared with suitable contacts, is mounted on a printed circuit board and potted in a clear plastic compound. The sample and connections are visible and at the same time are protected from external hazards. The connections to the sample are shown in Fig. 1.

|

Figure 1 - Contacts to the germanium sample.

|

Contacts 2 and 3, applied to the ends of the bar, are ohmic. Contacts 1 and 4 are "point" contacts, made in such a way as to permit the generation and collection of minority carriers. The four leads from these contacts terminate in a four-pin Jones plug that inserts into the matching socket of the bias supply unit. The two holes in the sample mounting board enable the germanium sample to be mounted on the manipulator. It is recommended that the sample be retained in this position throughout the experiments to reduce any unnecessary stress on the cable.

The Manipulator

The manipulator, which is held by two screws to the front panel of the bias supply box, provides a means of moving the sample through a distance of approximately 15 mm. This is required for the minority carrier lifetime measurements. One complete turn of the screw moves the sample through 0.5 mm.

The Light Source

The light source consists of a 6.5 Volt, 2.75 A, pre-focussed lamp, installed in a housing along with a lens system which produces an intense spot of light. A cover with a small aperture is supplied, and this is suitably placed over the sample so that only a very small pinpoint of light falls on a particular part of the sample. The position of the sample can then be adjusted using the manipulator. The light source plugs into the two-pin socket on the side of the bias supply that, in turn, is connected to a transformer inside the box providing the required current and voltage. An on-off switch, adjacent to the socket, operates the light.

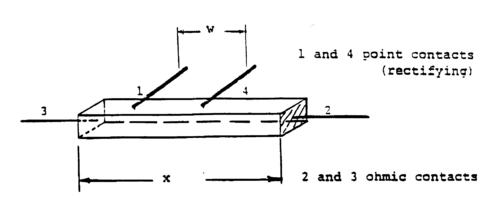

The Current Bias Supply and Pulse Generator

The DC current bias required for the various experiments is supplied from two 9 V batteries. A potentiometer, connected across the batteries, provides a continuously variable current from 0-1 mA, which is monitored on the milliammeter located on the front panel. The milliammeter is located on the front panel. The milliammeter is provided with an internal shunt that enables the meter to record either 0-100 μA or 0-1 mA, by selecting the appropriate range using the range selector switch below the meter. The current direction can be reversed using the reversing switch marked (+ OFF - ) on the front panel. The current passes through the germanium sample either through contacts 1 and 2 or through 3 and 2 depending on whether the contact switch on the front panel is set at "RECT" or "OHMIC" respectively. The voltage arising across the pairs of contacts 1 and 2 or 3 and 2 can be measured by connecting a voltmeter to the outlets of the supply unit, marked "OHMIC" or "RECT".

|

Figure 2 - Bias Supply and Pulse Generator Circuit Diagram.

|

A pulse generator is incorporated in the supply unit. It is produces a positive square pulse of approximately 100 msec with a repetition rate of approximately 10 milliseconds. The pulse height can be adjusted continuously from 20 to 40 Volts into a 200 Ω load (typical resistance of a germanium sample). The switch and potentiometer controlling the pulse generator, which operates from a 115 V, 60 Hz supply, are located on the front panel to the right of the meter. The supply is protected with a 0.5 A fuse situated at the side of the box. With the contact switch in the "RECT" position, the pulse output is fed internally to contacts 3 and 2 of the sample via a four-pin Jones plug. The pulse height can be measured by connecting the oscilloscope to the outlets labelled "pulse output" on the front panel.

Applying a positive pulse across contacts 3 and 2 of the sample causes the point contact numbered 4 on the sample to become reverse biased and a small reverse current will flow between it and contact 2. This current is measured by connecting the oscilloscope to the outlet labelled "oscilloscope" and observing the voltage arising across a 50 KΩ variable resistor labelled "collector bias" in series with the point contact 4. Adjusting the "collector bias" varies the reverse voltage applied to the point contact. The circuit diagram for the bias supply, pulse generator and sample is shown in Fig. 2.

Note: To install or replace a battery, disconnect the sample and remove the two screws at the front of the cabinet. The whole of the front panel of the cabinet then swings up, clearly exposing the battery holder and its connections.

Ohmic and Rectifying Contacts

Contacts between a metal and a semiconductor, or between two semiconductors, play an important role in the operation of semiconductor devices. Two types of contacts are known:

- ohmic contacts, for which the current-voltage characteristic is symmetrical and obey Ohm's law;

- rectifying contacts, for which the current flows more easily in one direction.

Ohmic contacts can be difficult to achieve in practice, particularly when making contacts with pure semiconductor material.

Apparatus

- N-type germanium sample with two point contacts

- Current bias supply

- Multirange voltmeter

Procedure

- Connect the sample to the four-pin socket on the side of the supply unit. Switch the contact switch to "OHMIC". This permits the current to flow through the two ohmic contacts 2 and 3 at the ends of the sample. (See Fig. 1).

- Set the current switch to '+' and connect the multi-range voltmeter across the orange and black sockets marked "OHMIC" on the supply unit.

- Select a suitable range on the ammeter and voltmeter and take a series of readings of millivolts for various currents in the 0 - 1 mA range.

- Turn down the bias to zero, switch the current to '-' and repeat the experiment.

- Set the contact switch to "RECT". This permits the current to flow through the point contact or rectifying contact 1 and the ohmic contact 2 on the germanium sample (See Fig. 1). Connect the multi-range voltmeter across the green and black terminals marked 'RECT' on the unit.

- Repeat steps (d) and (e) taking a series of voltage readings in the range 0-1 mA for current in the '+' direction in steps of 100 mA.

Turn the bias down to zero and switch to '-'. Repeat steps (d) and (e) taking a series of current readings for the voltage range 0-3V.

NOTE 1: Do not exceed 3 Volts as breakdown may occur which can permanently affect the characteristics of the point contact.

NOTE 2: If the multi-range voltmeter used has low input impedance then the meter itself can contribute an influence over the readings. Corrections can be made by repeating the experiment, without the sample, using the same meter ranges and by making the necessary adjustments to the first set of readings.

- Plot a graph of voltage versus current on a linear scale, for readings obtained with the contact switch in the "OHMIC" position.

- Plot a graph of current versus voltage on a log/linear scale for readings obtained with the contact switch in the "RECT" position.

Questions

- Use the observed current-voltage characteristics to comment on the type of contacts.

- Explain the behaviour obtained for rectifying contacts; refer to equation (1).

- How does the slope in the forward direction compare with the theoretical value?

- Discuss any deviations from the linear portion of the graph. Estimate the saturation current of this ‘diode’ from both the forward and reverse characteristics. Discuss the difference between ohmic and rectifying contacts.

- What can we learn about minority carrier injection from this experiment?

Drift Mobility of Minority Carriers in a Semiconductor

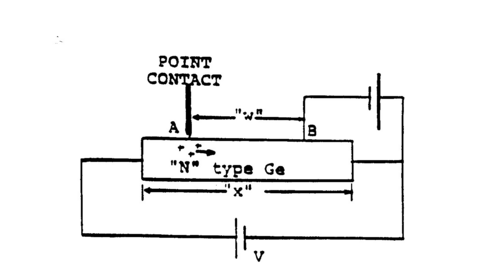

The previous experiment led us to conclude that excess carriers can be injected into a semiconductor by forward biasing a rectifying point contact. Consider a bar of n-type geranium into which minority carriers (holes) are injected at a point contact A. (See Fig. 3).

|

Figure 3 - Germanium bar with point contact.

|

If a voltage V is applied across the ends of the bar, then the holes will drift along the bar towards the negative contact with an average velocity proportional to the applied electric field. If a rectifying contact is placed at point B and is reverse biased, then the electric field set up at B will be such as to attract the holes as they pass, enabling them to be collected and detected.

It is important to note that the holes will only be detected at B if the time taken to travel from A to B is considerably less than the average lifetime of the injected carriers.

The average drift velocity of the minority carriers v (cm/sec) is given by

| (2) |

where μh is the mobility of the holes (cm2/volt sec.) and E is the applied electric field (volts/cm) given by E = V/x, where x is the length of the bar.

If w is the distance between A and B and t is the time taken for the carriers to move from A and B then:

| (3) |

or,

| (4) |